Techflow Enterprises Pvt Ltd is well one of the considerably qualified and most extensive suppliers of outcomes like Pulse Jet Bag Filter for shot blasting, Furnace Fume, Bag House, Extraction System, Dust Recovery System, Online Cleaning Bag Filter, Air Pollution Control Device, ESP, Flue Gas Emission Control System, Electrostatic Precipitator, Centrifugal Fans & Blowers, De-Dusting System, Bag Filter, Silo Vent Filter, Cassette Type Filter, Air Pollution Control Equipment, Welding Fume Extraction System, Fabric Filter, Pneumatic Conveying System, Reverse Air Cleaned Bag Type Dust Collector, Offline Cleaning Bag Filters to different industries domestically and all over the globe.

Techflow Enterprises Pvt Ltd has been supplying essential tools to innumerable industries like Mining and Minerals, Particle Board, Boilers Flue Gas, Manufacturing, Coal Handling, Cement, Air Pollution Control Systems, Solid Drying, Wood-Working & Laminates, Foundry & Steel, Glass, Hot Gases and Fumes, Kiln Exhaust, and many more industries.

Discover more| Bag Filter For Shot Blasting |

|---|

Bag Filter for shot blasting operated to induce steam for Sugar Mills, Power Plants, Chemical Plants, Process Houses, and many more. To develop steam these Bag Filter for shot blasting utilize Electricity which is Renewable Energy, Oil, Gas, LPG, and, Solid Fuels. Out of all fuels, the most affordable and the most used source is solid fuels. Wanting to keep this solid fuel emission, TECHNOFLOW offers a pollution control system that is remarkably efficient. These systems are globally known by multiple terms like Bag Filter for shot blasting, Pulse jet bag filter, Pulse jet bag filter, De-dusting system, ESP for boiler, Baghouse, and Bag Filter. |

There are many different kinds of supplies for pollution control to stop the emission from different types of solid fuels like Bag Filter for shot blasting, waste incineration boilers for trash to energy plants, Bag Filter for bagasse fired, Bag filters for Coal-fired boilers, bag filters for wood-fired boilers Bag Filter for food and agriculture waste fired boilers. TECHFLOW proudly delivers all of them as instructed.

|

1. Online Cleaned Pulse Jet Bag Filter for shot blasting

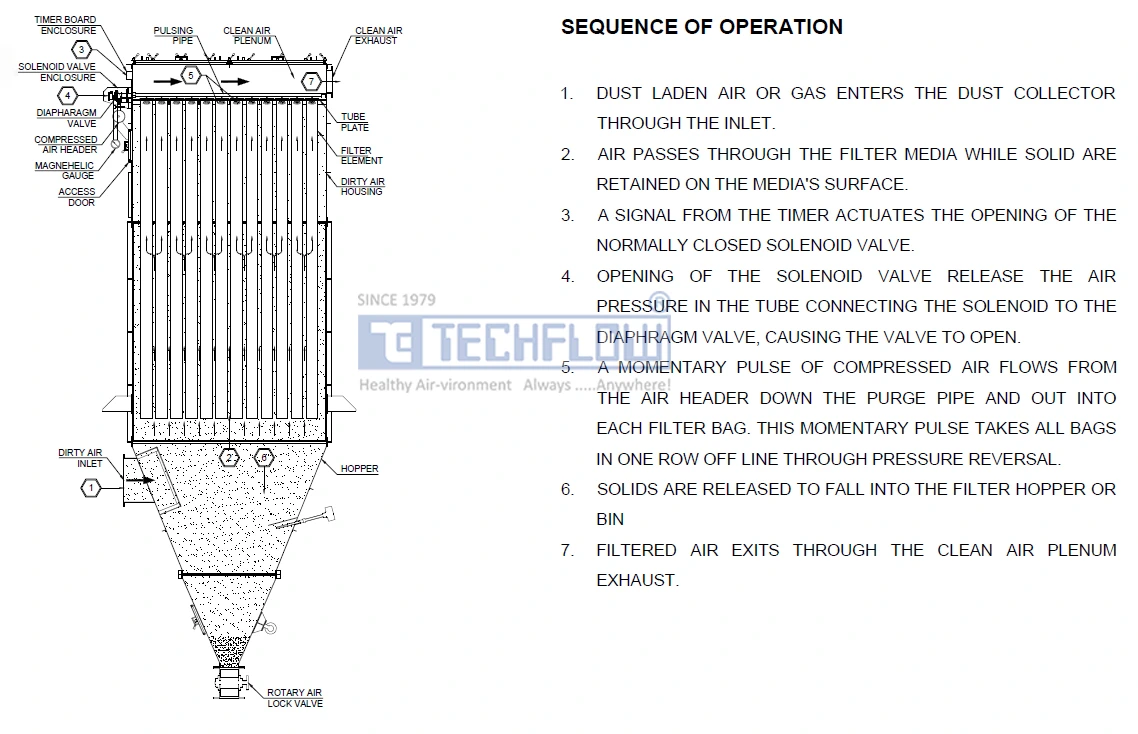

Where the weighty molecule drops out from the air stream, the dust-loaded air penetrates the collector. The lightweight molecules get entrapped in the air which as an outcome rise into the filter bags.

The passing air through the filter bags results in the dust molecules being collected on the outer surface of the filter bags as the filtered air gets exhausted via the collector called a hopper. The jets of consolidated air, at exact openings, go through the venturis thru blowpipes and pulse. This carries a briefly inverting strong flow of secondary air via the bags. This guides to the production of an inner shock wave that makes the bag full of pressure and mold outside as the shock gets down the length of the bag. The method permits the dislodgement of the dust of the inverted airflow on the outer side of the bag, which then sinks into a collection hopper. Airflow via a row of bags is reversed through this approach, but just for a bit of a moment. These then outcomes in a continuous state of airflow, Throughout the dust collector. The Cleansing Operation is effortlessly handled and adjusted Via a Solid State timer. The ideal regulation of the timer is promoted and handled by a differential pressure gauge. To minimalize the pressurized air consumption in the strategy, the pulse gap and durations can be exactly adjusted at the timer.

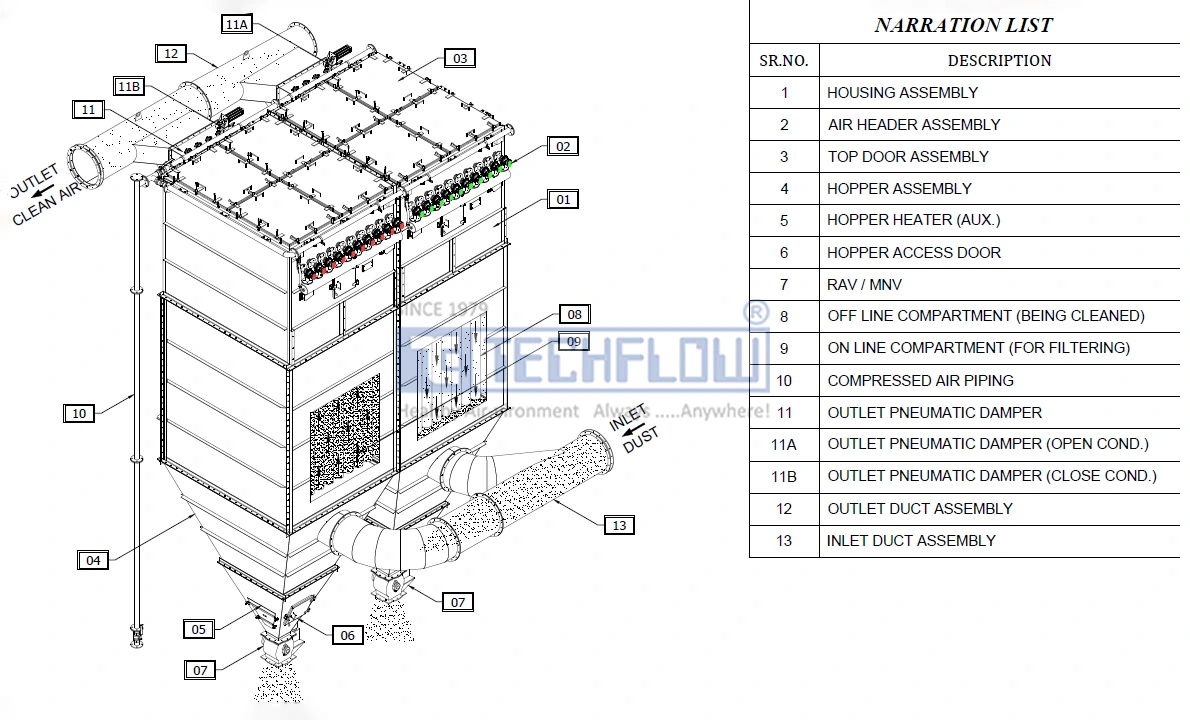

2. Offline Cleaned Pulse Jet Bag Filter for shot blasting

Partition of Pulse-Jet bag houses is also probable. In this method, the flow of the dirty air into the compartments is handled by the Isolation/Poppet valves adjusted in the hygienic air plenum. There is a selection to prepare individual compartments with either a single pulse valve that delivers the set of bags with air which is pressurized or have the pulsing air blown directly into the blowpipes that are next the bag rows in the compartment via different pulsing valves. The air that flux via the compartment is eradicated during the cycle of cleansing as the isolation damper exits. For the cleansing procedure, an air blast is delivered into the bags via the opening of the pulse valve for about 0.2 seconds. For the span of the pulsing procedure, the compartment stays offline. The duration for that, can be longer or shorter as per the necessity. The compartment is conveyed back on stream on the intuitive reopening of the Isolation/Poppet. Via Off-line Cleansing, until and unless every bag in the baghouse has been cleansed the alternate compartments are consecutively cleansed. While the baghouse every time achieves lower emission levels, It permits very specific bag cleaning as it is every time utilized on fabric filters installed on lower bulk density dust.